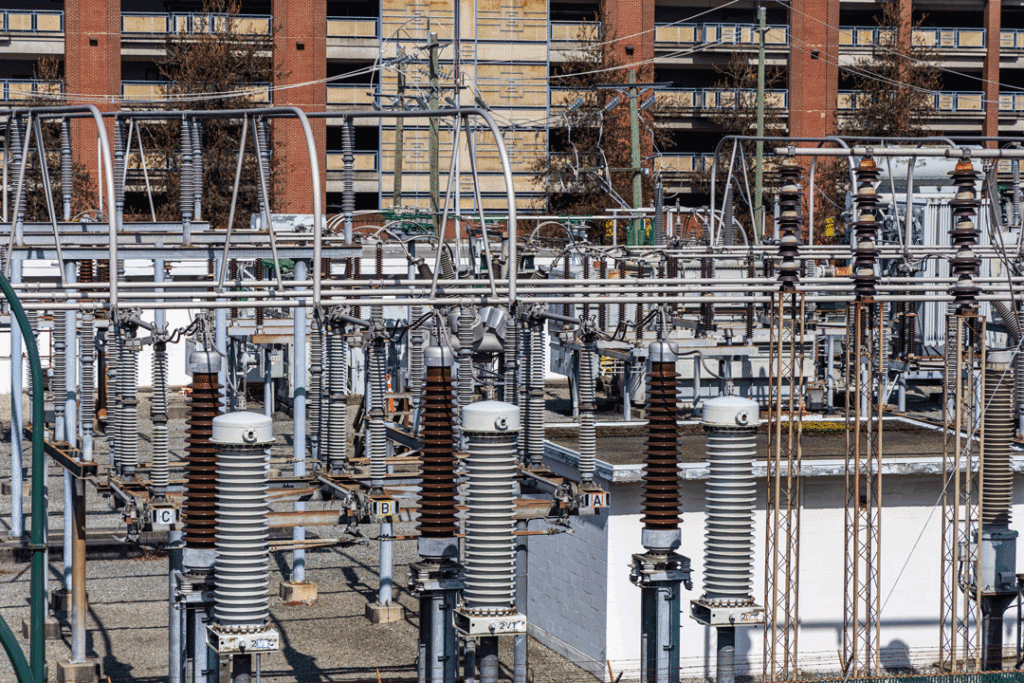

Climate scientists agree that extreme weather events are becoming more frequent. As a result, utility providers will continue to face growing challenges. For example, substations are the backbone of power distribution, yet they are often located in remote or exposed areas. Traditional monitoring methods, either on foot or by helicopter, are time-consuming, costly, and carry safety risks – especially before or after severe weather events.

UAV inspections for substations are changing that equation, offering safe, efficient, and high-quality coverage even in extreme weather.

Why Substation Monitoring Needs a Rethink

Substations are vulnerable to high winds, flooding, sandstorms, and extreme heat. These events can damage components, accelerate wear, and disrupt service for thousands of customers.

Conventional inspections often involve:

- Long downtime while teams access remote sites

- Limited visibility of high or hazardous components

- High costs linked to labour, transport, and safety measures

Drones offer a faster, safer, and more precise way to identify risks before they turn into outages.

How Drones Improve Substation Monitoring in Extreme Weather

Rapid Deployment in Hazardous Conditions

When weather hits, response time is critical. UAVs from automated drone docks can be launched on-site within minutes of clearance, avoiding the delays caused by moving large crews or equipment. This speed enables faster triage and helps maintenance teams prioritise repairs to restore service sooner.

Safe Access into Hard-to-Reach Areas

High-voltage lines, tall transformers, and elevated busbars are dangerous to monitor manually, especially after storms or in windy conditions. Drones used for site inspections capture high-resolution imagery and thermal data from a safe distance, removing the need for scaffolding, bucket trucks, manual rope climbing or other potentially unstable access methods.

Detailed Data for Smarter Decisions

Modern inspection drones can carry multiple sensors, including:

- Thermal cameras to detect overheating components

- UV sensors help detect corona loss, which normal sensors cannot detect

- High-zoom optical lenses for close-up fault detection

These datasets give engineers a clear, non-contact view of asset condition without stepping foot in hazardous zones.

Cost and Time Savings

Drone inspections reduce man-hours, transport costs, and equipment hire. For many utilities, they replace or supplement helicopter flyovers, lowering fuel use and emissions. In documented programmes, time and cost reductions of 30-70% are common, depending on asset type and workflow.

Real-World Applications in Extreme Weather

Post-Storm Damage Checks

After high winds or heavy rain, drones can visually inspect a small to medium substation in about an hour, identifying cracked insulators or displaced components.

Heatwave Monitoring

Prolonged high temperatures strain transformers. High-resolution RGB sensors can help detect minute or intricate faults, which can lead to disaster.

Flood Risk Assessment

Drones can assess floodwater ingress points and capture aerial views for planning repairs, avoiding the need to send crews into hazardous zones.

Integrating Drones into Utility Operations

Adding drones to monitoring and inspection workflows builds capability that includes:

- Training pilots to operate safely in complex environments

- Integrating drone data into asset management systems

- Creating response protocols for different weather scenarios

Companies such as FEDS support utilities through these steps, ensuring drones deliver value from day one.

Final Thoughts

Extreme weather isn’t going away, and neither is the need for reliable, efficient substation monitoring. Drones give utility service providers and transmission companies a proven way to cut inspection times, improve safety, and capture high-quality data for fast, informed decision-making – whatever the weather.

Contact recognised drone inspection experts at FEDS to explore ways to improve your utility monitoring and boost your grid’s resilience year-round.

How are drones used for substation and infrastructure inspection?

Drones capture close-up images and thermal scans of transformers, insulators, and conductors without interrupting operations. In post-event recovery, a small to medium site can often be evaluated in about an hour.

Can drones operate safely in extreme weather?

Most inspections are carried out after a weather event. Industrial UAVs like the DJI M400 are rated for moderate wind (~12 m/s), light precipitation (IP55), and −20 °C to 50 °C operation. Pilots adapt routes and timing to stay within these limits.

What data can drones collect during monitoring?

RBG imagery, thermal data, LiDAR measurements, UV readings and even gas-detection readings are possible with the right payloads.

How do drones compare to manual inspections?

A manual team might take a full day to cover one substation. A drone can often complete the same visual inspection in a fraction of the time, cutting labour hours by 30-70% while improving data quality.

How quickly can drones be deployed after a weather event?

With trained crews and established protocols, deployment can occur within minutes of site clearance, enabling rapid fault prioritisation. And if the substation has automated drone docks installed, the UAVs inside them can launch in under 30 seconds.

Mapping Underground Utility Networks: Drones + Ground Penetrating Radar

Combining drones with ground penetrating radar transforms utility mapping, making…

Read

Drones for Substation Inspection: Boosting Grid Reliability in Extreme Weather

Climate scientists agree that extreme weather events are becoming more…

ReadSubscribe to our newsletter

Get the latest drone news and updates sent straight to your inbox.

Subscribe